Pipeline Integrity Assessment

Based on inspection data, pipeline integrity engineers can provide a complete integrity assessment of the pipeline. Individual corrosion features are assessed on their severity and potential risk. Corrosion growth can be assessed based on comparison with previous inspection runs. Inspection data can be integrated in a Fitness for Purpose Analysis, which prioritizes the maintenance and repair activities. External factors such as environment, human interference, soil and population are combined with the results of the Fitness for Purpose report to generate a Risk Based Assessment.

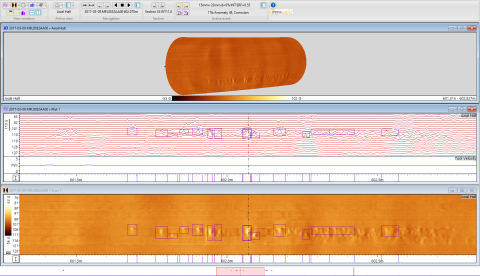

As part of the service, all inspection reports come with raw processed data and the latest version of DATsurvey. With this extremely powerful and user-friendly Interface the customer can review the inspection data. One can navigate through the pipeline on variable scale, create custom views, print dig verification sheets and analyze histograms. DATsurvey has the capability to synchronize results of various inspection runs. This significantly contributes to the confidence level of the integrity assessment.

Pipeline defect assessment can be delivered in accordance with ASME B31G, DNV RP-F101, R-Streng or any other defect assessment method as per customer specification, national code or law. All services provided by Pipesurvey International are in full compliance with the latest standards of Pipeline Operator Forum, API 1163, ASNT-PQ-ILI-2010 and NACE-SP-102.