Cracks

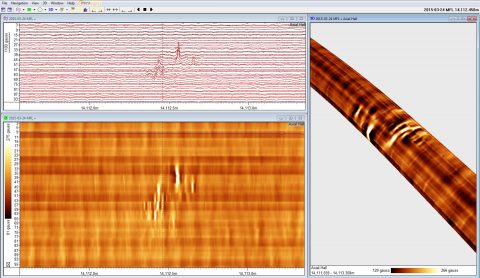

MFL and C-MFL technology

Crack-type defects with opening of more than 0.2 mm have been made visible by special signal processing of MFL signals. Regular MFL technology has been used to assess crack-type defects in girth welds, whereas C-MFL type signals are used to detect axially oriented crack-type defects.

Cracks can occur either individual or in colonies and they may appear in the pipe body or be associated with circumferential or longitudinal welds. The difference between cracks and crack-type defects is that cracks are true planar anomalies, which means they have a length and a depth but no width. Crack-type defects on the contrary are associated with an opening of the pipesurface and can be detected by means of MFL technology.