Pipesurvey USA

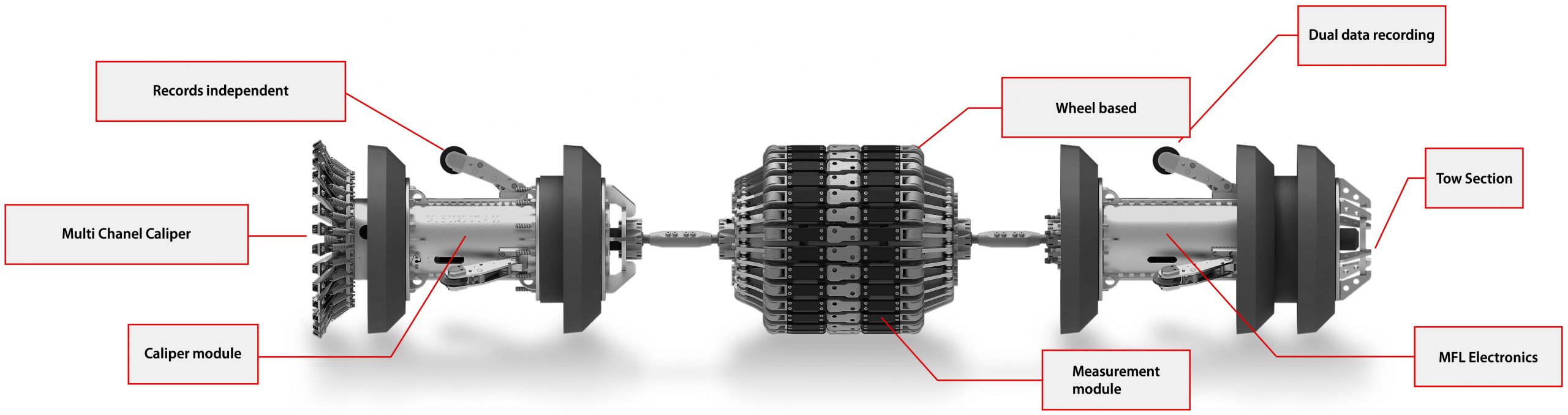

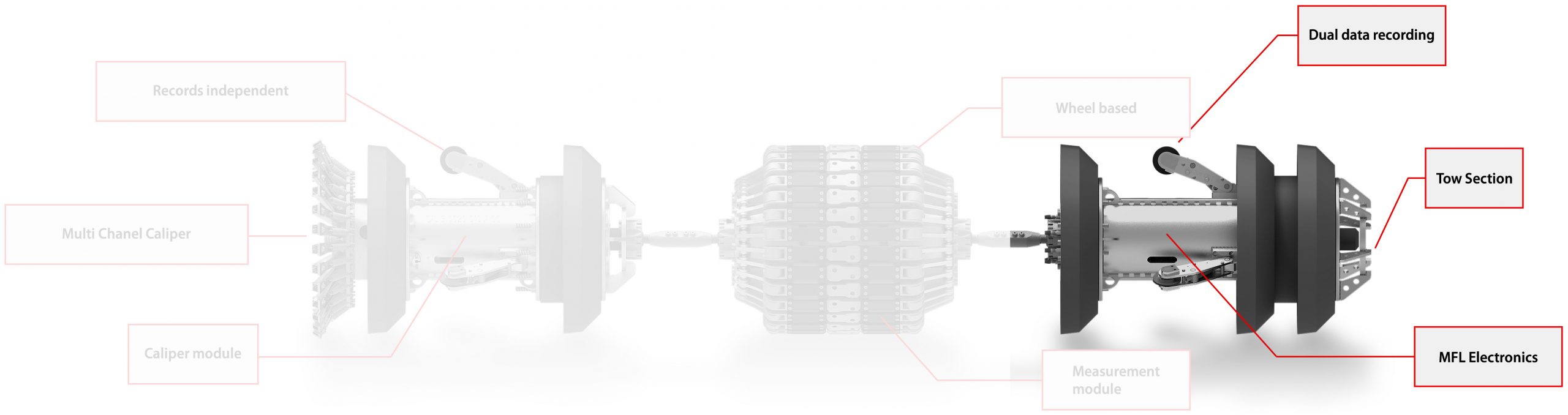

- MFL Electronics Module (point at main canister (where the left dot is)

- Houses Electronics, Data Storage, Batteries and IMU

- Integrated high resolution IMU/XYZ conforms to WGS84 Standard

- Dual data recording – both distance and time based data. (point at Odometer (wheel at the top of the tool, sticking out)

- Tow section can be changed out for tether MFL applications (point at toe section – the metal part on the very right of the tool)

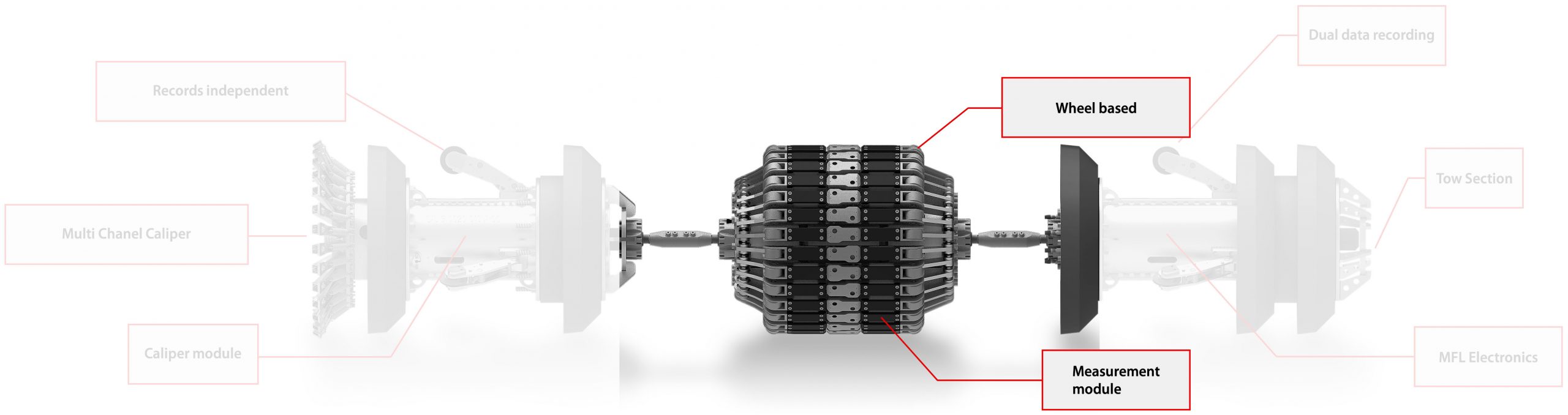

- Measurement Module (point at the center)

- UltraHigh Resolution MFL

- Tri-Axial Hall sensor for complex corrosion and pin-hole detection

- Integrated Secondary ID/OD sensors makes for compact design

- Mag-bar Based design for improved flexibility

- Wheel based yoke to reduce friction and stabilize velocity (this can stay here, or pull out on its own, pointing at where you have the right-side position)

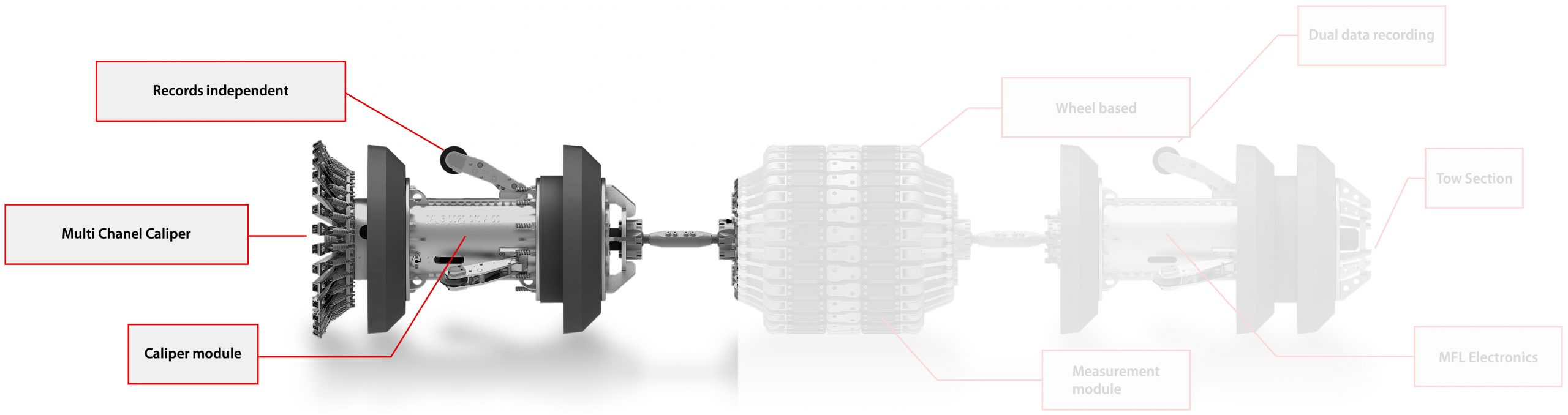

- Caliper Module (point at the center

- Detachable to run as stand-alone caliper, for maximum flexibility in the field

- Multi-Chanel caliper (this can stay here, or get pulled out on its own, pointing at the fingers at the back)

- Records independent time and measurement based data. (this can stay here, or be pulled out pointing at the odometer wheels like on the mfl module)

Analysis Solutions

- Reporting

- Formatted to integrate seamlessly with your PODS system

- POF standard nomenclature, modifiable to yours standards

- Customizable remaining strength calculations

- Delivery Timing

- Field verification 24-28 hours

- Preliminary report – 14 business days

- Final Report – 30 business days

- Expedited reporting available

- Data

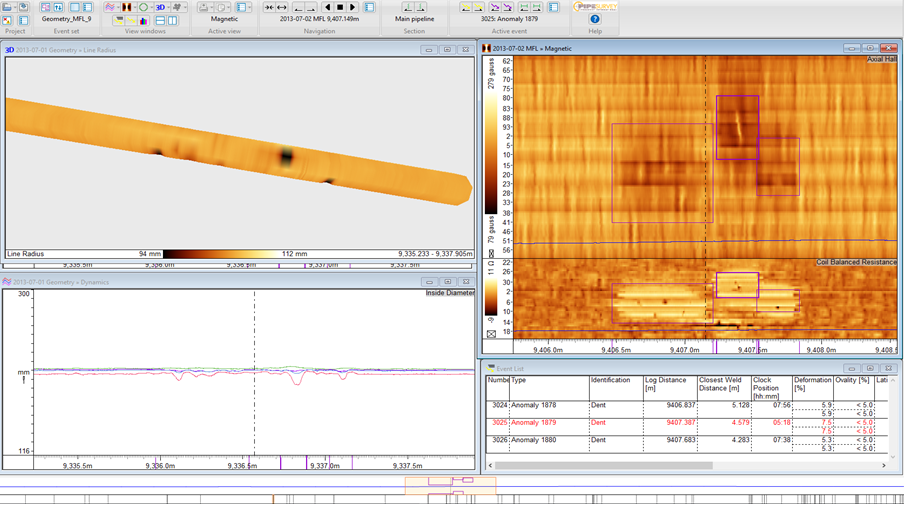

- DATsurvey data viewer provided

- No installation required

- No license required

- Raw-processed data provided at no charge

(put the datasurvey picture in this section)

- DATsurvey data viewer provided

- Advanced Analysis

- Fit For Purpose Assessment

- Dent Strain

- Bending Strain (single line, and comparative)

- Corrosion Growth Assessment

- Recommendations on ILI program and inspection frequency

Quick Turn Around

- Field reports available in 24-48 hours

- Preliminary report in 14 days

- Final report in 30 days.

- Expedited reporting available

Fleet Information

- Internationally proven experience since 2002.

- Houston based fleet (6” – 36”)

- Additional sizes available from Pipesurvey International

Custom Solutions

- Dual-diameter and Multi-diameter fleet available

- We will create customized size combinations for your applications.

- Low Flow expertise

- Longest run – 20”x52 miles run over 27 days.

- Customizable for your needs

- High Flow/High Speed

- Active Speed control available.

- Speed control adjusts to line conditions every 10 seconds

- Tethered and Bi-Directional

- BiDirectional fleet available

- Both 1 sided or 2-sided tether applications.

Hazardous products – (I think we should leave this off for now, as we have not decided if we will target these markets and we don’t have equipment available at this time.)

About Us

Pipesurvey USA, LLC is a partnership founded in 2019 between Pipesurvey International and Invacor to bring world class, proven in-line inspection tools and software to the US market. Headquartered in Houston, TX, Pipesurvey USA’s highly skilled engineers, operators and data analysts provide a broad range of experience and expertise to meeting the unique needs of US pipeline operators.

Pipesurvey International has continually advanced and evolved inspection technologies to meet evolving global needs since 2002. This includes creating bi-directional and multi-diameter solutions, as well as expertise operating in challenging flow regimes. Pipesurvey International consists of creative and skilled engineers with a dynamic pioneering-spirit who are passionate about solving pipeline threats, including the tool and software’s original creators.

Together, Pipesurvey USA and Invacor offer a full suite of pipeline integrity services, either stand-alone or as total integrity solutions with one team, one quote, and one invoice.